Customers who are saving Millions of Dollars in Downtime Cost with Nanoprecise Solutions

.png)

Oil & Gas Application Value Creation

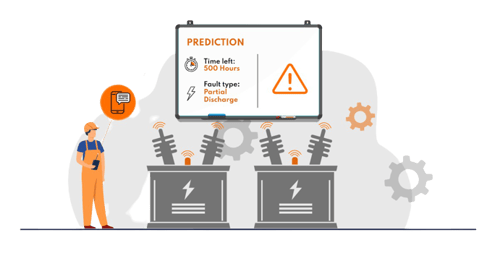

Accelerate the performance of your assets with AI-based Predictive Maintenance

Say No to Unplanned Downtime

Every industry has its own set of challenges when it comes to maintaining its assets. In the oil and gas sector, the challenges are even more complicated. Companies are battling the need to increase production while lowering operational costs with improved worker safety. With diverse and complex equipment sets often placed in hard-to-reach, remote locations, the challenge of frequent monitoring is huge. Real-time insights on machine health and performance of offshore pumping station, compressor, drilling rig, transportation equipment, pipeline booster station, or any other critical piece of machinery throughout the upstream, midstream and downstream processes, helps maintenance and reliability professionals to make faster and accurate decisions, that drive efficiencies and improve the competitive advantage

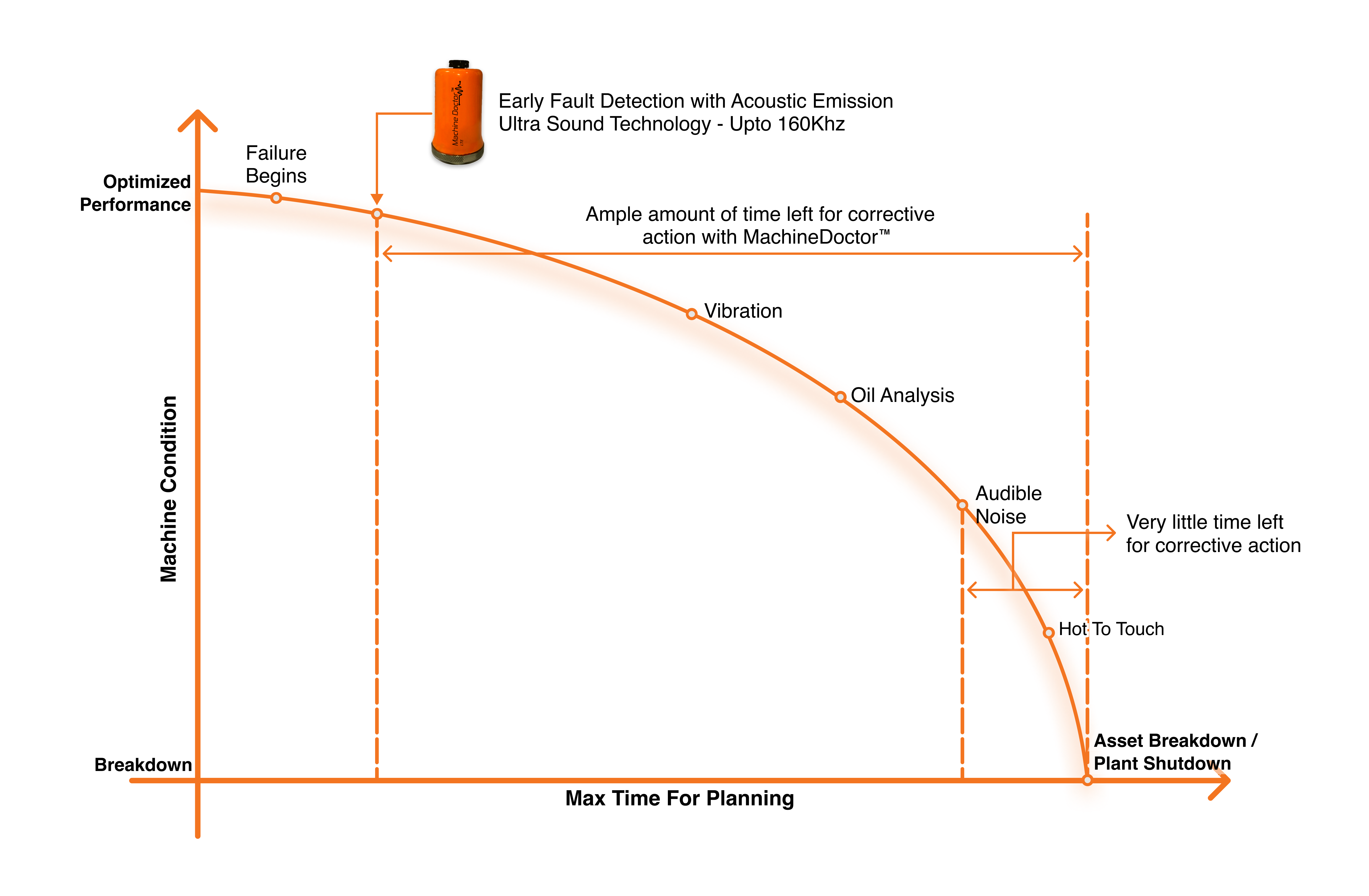

Increase Asset Life with Acoustics + AI

Sound is the earliest indicator of failure and Operators have been using sound to gauge the condition of the machines for a long time. During high noise, the equipment may still continue to operate within required parameters, but when left unaddressed, its health will start to deteriorate at a faster rate until the motor completely breaks down. However, in most cases, the distinction in sound is not heard in time to prevent unplanned downtime.

MachineDoctor is the state-of-the-art wireless industrial IoT hardware that captures acoustics emissions to detect anomalies in the operating parameters of the machine and predict failures.

Applications We Cover

How it works

Play

Play